Good Quality Ceramic PCB Manufacturer in the world and China

Ceramic board is a type of board made from ceramic materials and sintered at high temperatures. It has the characteristics of high hardness, high corrosion resistance, and high temperature stability, and is widely used in fields such as construction, electronics, and chemical engineering. Ceramic pcb boards are actually made of electronic ceramics as the basic material and can be made in various shapes. Among them, the characteristics of high temperature resistance and high electrical insulation of ceramic circuit boards are the most prominent. The advantages of low dielectric constant and dielectric loss, high thermal conductivity, good chemical stability, and similar thermal expansion coefficient to components are also very significant.

Pls send PCB files to sales1@hitechpcb.com to get a quote now!

1、 What is ceramic board?

Ceramic board is a type of board made from ceramic materials and sintered at high temperatures. It is mainly made of ceramic materials such as alumina and zirconia, and has the characteristics of high hardness, high corrosion resistance, and high temperature stability. Due to these characteristics, ceramic panels are widely used in fields such as architecture, electronics, and chemical engineering.

2、 What are the characteristics of ceramic panels?

- High hardness: Ceramic plates have a hardness of up to Mohs hardness level 9, which is more than 10 times that of metal materials, and can resist most mechanical impacts and wear.

- High corrosion resistance: Ceramic plates have high resistance to chemical corrosion from most acids, alkalis, and salts.

- High temperature stability: Ceramic plates have good stability at high temperatures and can be used in high temperature environments above 1000 ℃.

- Good insulation performance: Ceramic plates have good insulation performance and can be used in harsh environments such as high voltage, high temperature, and high humidity.

- Good wear resistance: Ceramic plates have good wear resistance and are not easily worn.

- Easy to process: Ceramic plates can be processed through cutting, stamping, drilling, and other methods, suitable for designs of various shapes.

3、 What are the applications of ceramic plates?

- Construction field: Ceramic panels are widely used in the construction field, such as exterior wall panels, ceramic tiles, etc. Their high hardness, high corrosion resistance, and high temperature stability make them resistant to adverse environmental effects such as air pollution and acid rain, and maintain long-term aesthetics.

- Electronic field: Ceramic plates are used in the electronic field, such as substrates, packaging, capacitors, etc. Due to their good insulation performance and high-temperature stability, ceramic plates can work in environments such as high temperature, high voltage, and high frequency without any changes in electrical properties.

- Chemical industry: Ceramic plates are used in the chemical industry, such as chemical reactors, pipelines, etc. Due to their high hardness and corrosion resistance, ceramic plates can resist the erosion of various corrosive substances and ensure the long-term stable operation of chemical equipment.

【 Conclusion 】

Ceramic board is a new type of board with high hardness, high corrosion resistance, and high temperature stability, which is widely used in fields such as construction, electronics, and chemical engineering. With the continuous development of technology, the application fields of ceramic plates will become increasingly widespread.

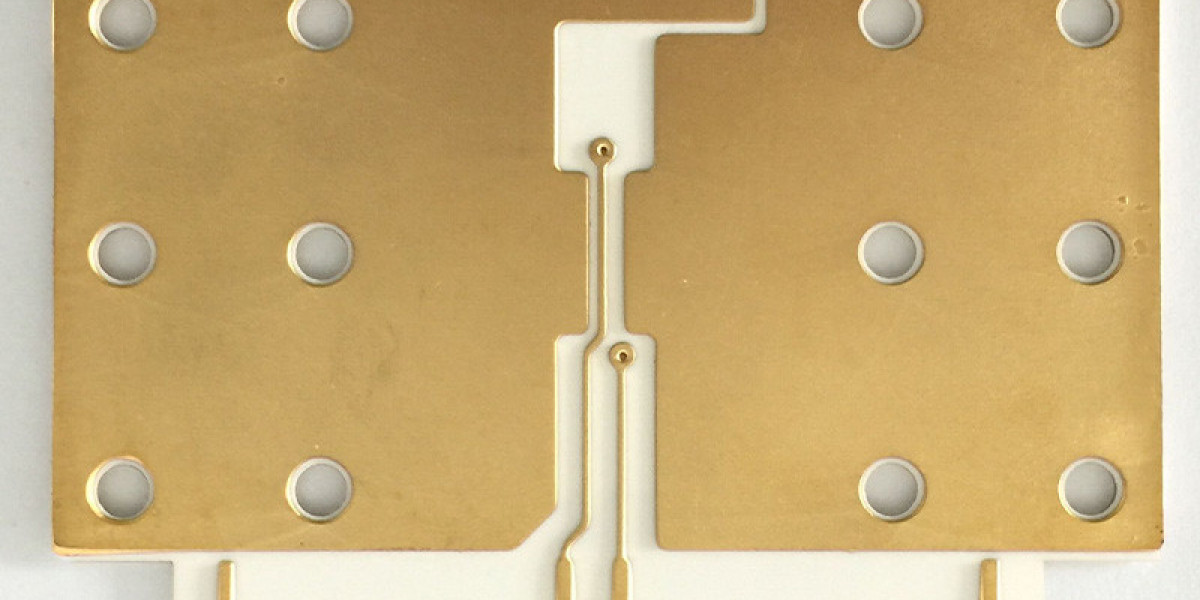

Different types of ceramic pcb

Ceramic PCB is widely used in power electronics, electronic packaging, hybrid microelectronics and multi-chip modules due to its excellent thermal conductivity and air tightness. But not everyone is clear about the classification. Many manufacturers think ceramic PCBs are expensive and fragile as soon as they hear about ceramic PCBs. Yes, this is indeed a shortcoming of ceramic PCBs, but not all ceramic PCBs are like this. Today we will tell you about the different types of ceramic PCBs.

Al2O3 ceramic PCB

Al2O3 ceramic PCB ( alumina ceramic PCB) refers to various ceramic PCBs with Al2O3 as the main raw material and an Al2O3 content of more than 75%. It has a rich source of raw materials, with advantages of low price, high mechanical strength and hardness, good insulation performance, good heat shock resistance, good chemical resistance, high dimensional accuracy, and good adhesion to metals. It is a ceramic substrate material with good comprehensive performance. Currently used Al2O3 ceramic substrates, the content of Al2O3 accounts for 85% to 99.5%. Among them, 96% Al2O3 ceramic PCB is widely used in the production of thick film circuit substrates and chip devices. The thermal conductivity of Al2O3 at room temperature is 29W/(m·K), which is close to the thermal conductivity of steel; with the increase of Al2O3 content, the electrical insulation performance and thermal conductivity of Al2O3 ceramic PCB will increase, but At the same time, it will also lead to an increase in the firing temperature, an increase in energy consumption, a large loss of kiln furniture, and an increase in manufacturing costs.

For more details, please visit https://hitechcircuits.com/pcb-products/ceramic-pcb/.