Understanding Gas Manifolds with Gauge

The combination of Gas Manifolds with Gauge functions as essential tools for both industrial facilities and residential kitchens to control gas flow distribution. These systems maintain uninterrupted gas distribution while providing secure supply conditions which improve operational performance alongside leak and fluctuation safety.

Why Are Gas Manifolds Important?

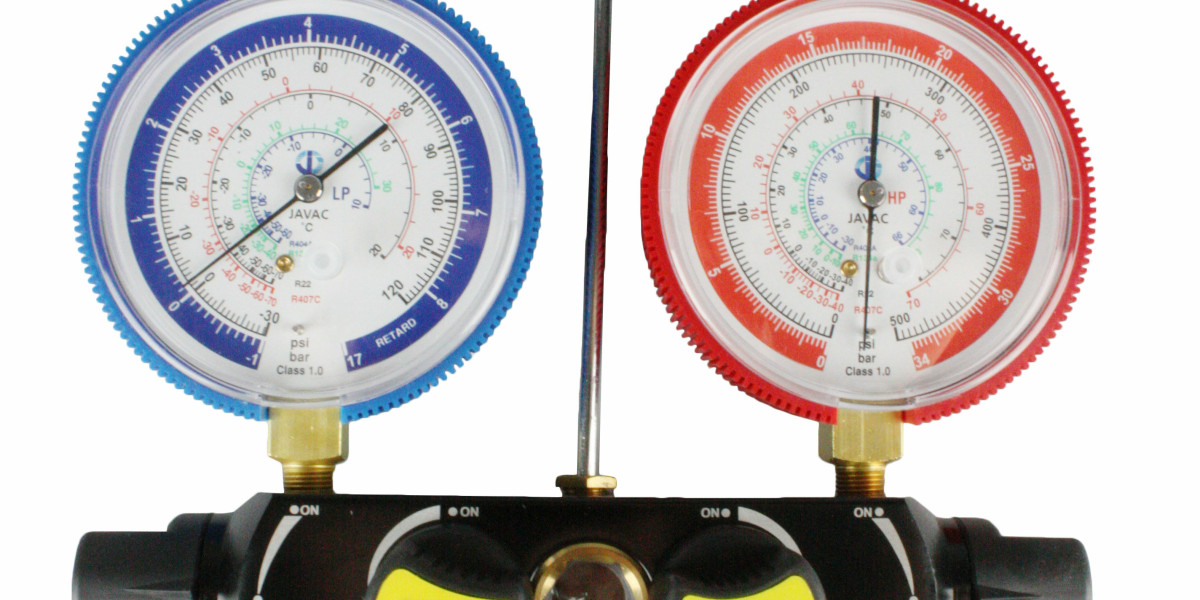

The gas manifold functions as a device to join numerous gas sources with single or multiple outlet channels to distribute gas effectively. Real-time pressure level monitoring is possible with gas manifolds which have gauges that ensure stable gas supply. Gas manifolds together with their built-in gauges serve their purpose best in commercial kitchens as well as laboratories and manufacturing units that require stable gas pressure.

The Functionality of a Gas Manifold with Gauge

Gas manifold pressure monitoring occurs through its built-in gauge which provides users with the following functionality:

- Track gas pressure in real-time

- The system detects unexpected changes which might cause harm before they occur.

- Improving gas consumption leads to more efficient and risk-free operations.

A gas manifold with a gauge provides a stable and sufficient gas supply to gas stoves used in restaurant kitchens and domesticate kitchens which leads to better performance alongside increased longevity.

Benefits of Using a Gas Manifold with Gauge

1. Enhanced Safety

Gas pressure variations cause inefficiencies together with harmful conditions that include leakages as well as combustion system breakdowns. Such issues are prevented by the gauge which provides ongoing observation.

2. Efficiency and Cost Savings

The efficiency of gas-powered equipment and the total cost efficiency of procedures improve when a gas manifold with a gauge maintains a steady supply of gas.

3. Versatility Across Applications

The same systems exist in multiple industrial sectors that contain medical sites welding facilities and food processing units thus guaranteeing gas availability without interruptions.

The Selection of an Ideal Gas Manifold with Measurement Indicator

The selection of a gas manifold requires an assessment of material quality pressure capacity and gas type compatibility. Stainless steel together with brass represents the preferred materials for gas manifolds because they offer strong durability alongside protection against corrosion.

Conclusion

A gas manifold joined to a gauge proves to be a wise purchase for users who operate gas stoves alongside other gas-powered systems. The component functions as a vital element in domestic and industrial gas pipelines because it ensures both operation security and process efficiency alongside dependability.