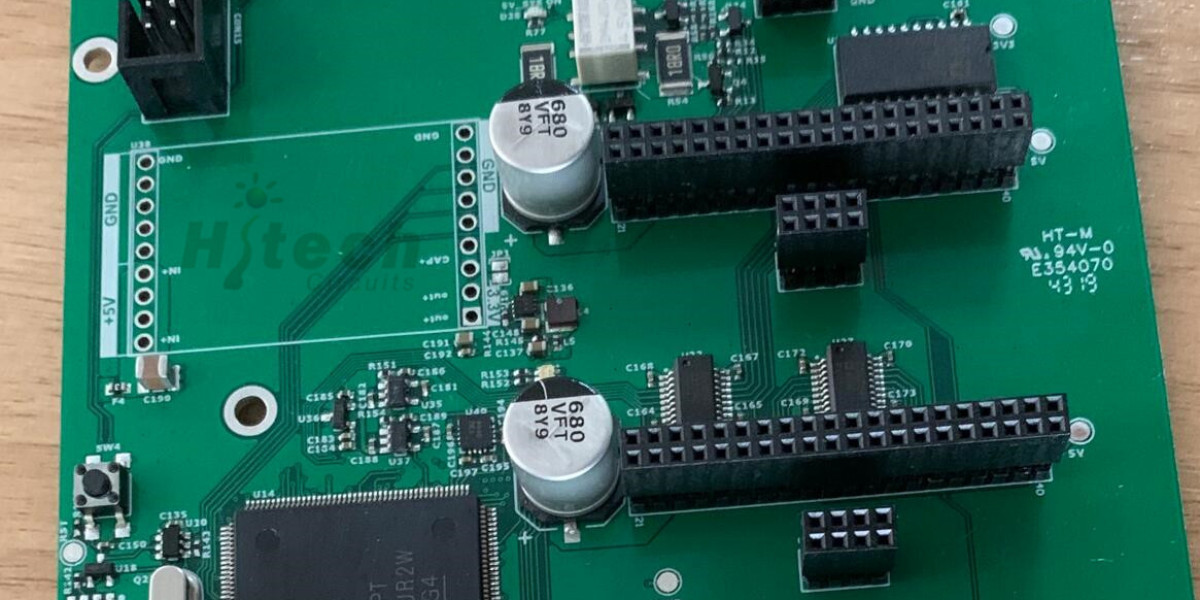

Medical PCB Assembly Manufactured in Shenzhen China with Good Quality

In the field of electronic devices, medical electronic devices have particularly strict requirements for PCB circuit boards due to their direct impact on human health and safety.

As a manufacturer specializing in medical equipment PCBA surface mount processing, Hitech Circuits Co., Limited will explore in detail the characteristics and working principles of medical electronic equipment PCB circuit boards, providing valuable reference for procurement personnel of electronic equipment manufacturers.

As leading one-stop PCB Assembly services provider in China, Hitech Group offers high quality, cost effective and express PCB board products and provides PCB manufacturing, electronics assembly manufacturing, components sourcing, Box build assembly and PCBA testing services for our customers. Pls send PCB files to sales1@hitechpcb.com to get a quote now!

1、 Characteristics of PCB circuit boards for medical electronic devices

- High reliability and stability

Medical electronic devices typically require stable and reliable operation over a long period of time, and any malfunction may pose a threat to the patient's life and health. Therefore, medical electronic equipment PCB circuit boards must have extremely high reliability and stability.

This requires PCB circuit boards to use high-quality raw materials, such as FR-4 materials with high heat resistance and low CTE (coefficient of thermal expansion), as well as special copper cladding layers that resist electromagnetic interference.

At the same time, it undergoes rigorous electrical testing, environmental testing (such as temperature cycling, humidity testing), and mechanical strength testing to ensure that it can still operate stably under extreme conditions.

- Compact layout and high integration

Medical electronic devices often require the integration of multiple functional modules and electronic components within a limited space, therefore PCB circuit boards need to have compact layout and high integration capabilities.

By adopting advanced technologies such as multi-layer board design, micro hole technology, and blind buried holes, medical electronic equipment PCB circuit boards can achieve higher component density and more complex circuit layouts in limited space, thereby meeting the demand for miniaturization and precision in medical equipment.

- Good anti-interference ability

There are various sources of interference in environments such as hospitals, such as electromagnetic waves. Medical electronic equipment PCB boards must have good anti-interference capabilities to ensure the normal operation of the equipment.

This requires PCB circuit boards to fully consider signal isolation and shielding during design, to avoid mutual interference between different electronic components.

- High security and isolation

Due to the direct or indirect contact of medical equipment with the human body, PCB circuit boards must have good safety and isolation to prevent any faults in the circuit from having adverse effects on humans.

For example, using antibacterial and corrosion-resistant surface treatment techniques such as gold plating, silver plating, or special chemical coatings to protect circuits from bodily fluids and reduce bacterial adhesion.

In addition, PCB circuit boards must comply with relevant electrical safety standards to ensure the safety of the equipment during use.

- Comply with medical standards and regulations

Medical electronic device PCB boards must strictly comply with relevant medical standards and regulations during the design and manufacturing process, such as ISO 13485 medical device quality management system certification, FDA (US Food and Drug Administration) regulations, CE mark (European Conformity Certification), etc.

This not only involves the manufacturing process, but also comprehensive requirements such as design, documentation, and traceability management.

2、 Working principle of medical electronic equipment PCB circuit board

- Line connection and signal transmission

PCB circuit boards connect various electronic components through circuit design and wiring, achieving signal transmission and power conversion. These signals can be electrical, analog, or digital signals.

Sensors in medical electronic devices collect physiological parameters of patients and convert these parameters into electrical signals through PCB circuit boards, which are transmitted to the main controller.

At the same time, the main controller will also transmit treatment information through the circuit board. Therefore, PCB circuit boards play a crucial role in signal transmission in medical electronic devices.

- Power management and thermal management

Medical electronic devices require a stable power supply to ensure operational reliability. PCB circuit board manages and controls power supply through circuit design and wiring, providing appropriate power for various functional modules.

At the same time, heat conduction and dissipation should also be considered in the design to ensure that the temperature of electronic components is controlled within a safe range during operation.

- Mechanical support and protection

PCB circuit board, as a whole structure, can provide mechanical support for electronic components, ensure the relative position of components is fixed, and protect components from external environmental influences.

In medical electronic devices, this mechanical support is particularly important because the equipment often needs to withstand various complex usage environments and conditions.

The PCB circuit board of medical electronic equipment plays a crucial role in medical devices due to its high reliability, compact layout, good anti-interference ability, high safety, and isolation.

Understanding these characteristics and working principles is crucial for procurement personnel of electronic device manufacturers, as it helps them make more informed decisions when selecting suppliers and evaluating products.

Meanwhile, with the continuous development of medical technology, PCB technology will also continue to evolve and contribute more to human health and well-being.

For more details, please visit https://hitechcircuits.com/pcb-assembly/.