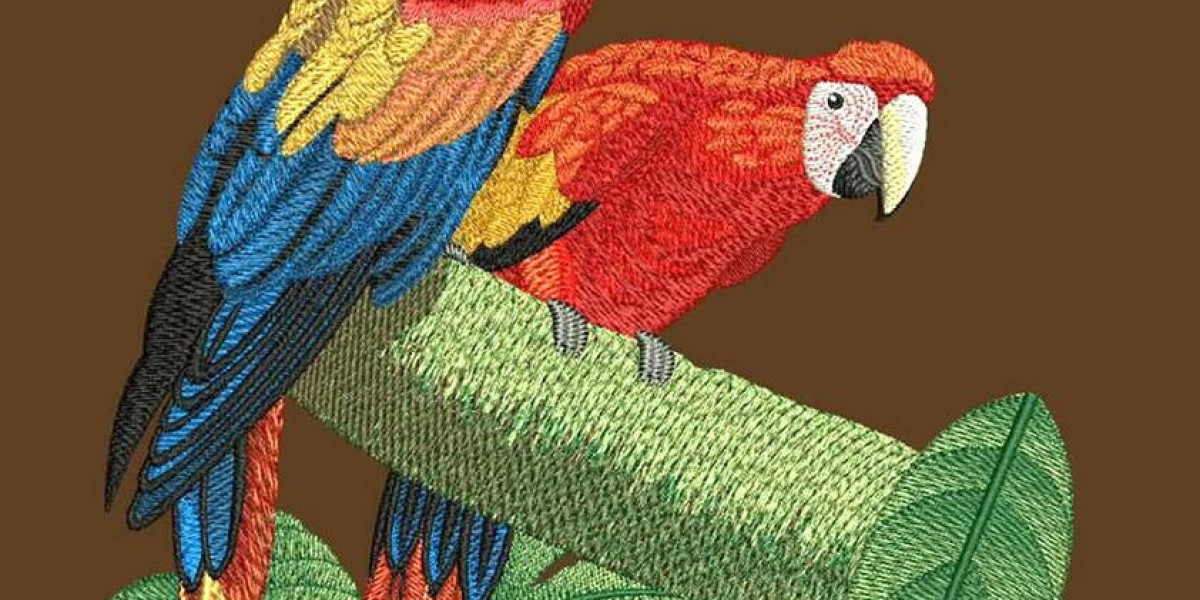

Embroidery has evolved from traditional hand-stitching to a modern, technology-driven craft. A digitizer for embroidery plays a crucial role in converting digital artwork into embroidery-ready files. Whether you're a beginner or an expert, understanding the embroidery digitizing process can help you create precise and high-quality stitched designs.

What is Embroidery Digitization?

A digitizer for embroidery is either a software application or a professional service that translates digital designs into stitch patterns that embroidery machines can read. These digitized files control stitch direction, density, and type, ensuring the embroidery is both aesthetically pleasing and structurally sound. Popular file formats include DST, PES, EXP, and JEF, which vary based on the machine's specifications.

Why is a Digitizer for Embroidery Essential?

Using an embroidery digitizer offers several key advantages:

Accurate Stitching – Ensures high precision and neatness in every design.

Customizable Patterns – Enables unique and tailored embroidery work.

Efficiency and Speed – Reduces manual adjustments and enhances workflow.

Consistent Quality – Ensures uniform designs across multiple embroidered pieces.

The Step-by-Step Embroidery Digitizing Process

Image Preparation – Modify and refine the design for embroidery compatibility.

Stitch Path Planning – Define the sequence and direction of stitches.

Choosing Stitch Types – Assign suitable stitches such as satin, fill, or running stitches.

Adding Underlay Stitches – Strengthen the design for stability.

File Conversion – Save the design in a format compatible with the embroidery machine.

Test Embroidery – Conduct a sample run to check quality before production.

Selecting the Right Embroidery Digitizer

Embroidery Digitizing Software

If you prefer to digitize designs yourself, investing in quality software is crucial. Popular options include:

Wilcom Embroidery Studio – Ideal for professionals with advanced design tools.

Hatch Embroidery – A user-friendly software suited for all skill levels.

Brother PE-Design – Great for home embroiderers looking for simplicity.

Embird – An affordable yet powerful option for detailed customization.

Hiring a Professional Embroidery Digitizer

If you opt for outsourcing, consider professionals who:

Have expertise in different embroidery file formats.

Offer quick turnarounds and revision options.

Provide detailed and precise stitch conversions.

Ensure compatibility with various embroidery machines.

Best Practices for Embroidery Digitization

Use the Right Stitch Type – Different elements require specific stitches for the best outcome.

Adjust Stitch Density – Prevent fabric distortion by balancing stitch density.

Consider Fabric Type – Optimize stitch settings based on material properties.

Always Conduct a Sample Stitch Test – Verify the design quality before mass production.

Conclusion

A digitizer for embroidery is an essential tool in achieving flawless and professional embroidery results. Whether you choose to use digitizing software or hire a professional service, having a clear understanding of the process ensures precision and creativity in your embroidery projects. By selecting the right digitizing solution, you can enhance the quality of your designs and bring your artistic visions to life with accuracy.

Frequently Asked Questions

What file formats do embroidery machines support?

Common formats include DST, PES, EXP, and JEF, depending on the brand and model of the machine.

How long does it take to digitize a design for embroidery?

Basic designs can be digitized within an hour, while intricate designs may take longer.

Can I learn embroidery digitizing on my own?

Yes, with the right software and consistent practice, anyone can develop embroidery digitizing skills.

What is the cost of professional embroidery digitizing services?

Pricing varies from $10 to $50 per design, depending on the complexity and level of detail required.

Are all embroidery machines compatible with digitized files?

Most modern machines can read digitized files, but format compatibility varies by machine brand and model.