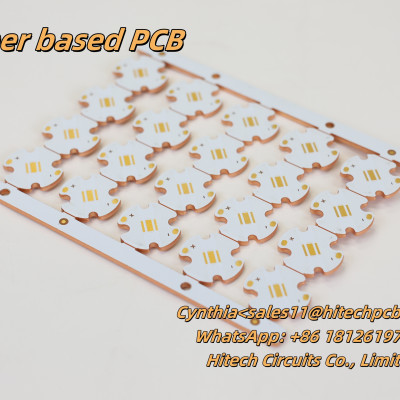

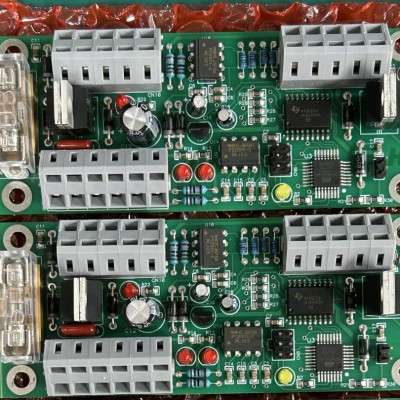

Green PCBA used in Industrial Area by China Manufacturer TOP 20 Made by Hitech Circuits Co., Limited

Published By PCB Assembly_HitechCircuits_Roger Luo

- Location中国

- StatusIn stock

- TypeNew

Green PCBA used in Industrial Area by China Manufacturer TOP 20

Printed Circuit Board Assembly Services

Printed Circuit Board Assembly is a process that requires knowledge not just of Printed Circuit Board components and assembly but also of printed circuit board design, Printed Circuit Board fabrication and a strong understanding of the final product. Circuit board assembly is just one piece of the puzzle to delivering the perfect product the first time.

Printed Circuit Boards (PCBs) are across many industrial and consumer electronics, used in products ranging from remote controls to military weaponry. The versatility of PCBs comes from their lightweight, compact, and flexible construction, which can be adapted to suit circuits of any complexity. Though PCBs are relatively commonplace, their complexity makes it critical to source new circuit boards from reliable suppliers. Printed Circuit Board Assembly services harness these complexities.

Hitech Group offers comprehensive Printed Circuit Board Assembly services that help our customers fully realize their designs. We have extensive experience working with customers in a broad range of highly innovative industries, including Communication, Aerospace & Defense, Automotive, Industrial control, Medical equipment, Oil & Gas, Security, and so on.

Printed circuit board assembly (PCBA) is the process of soldering electronic components to a PCB or printed circuit board. It is an essential step in manufacturing electronic devices and products. A finished PCBA contains all the necessary electronic components that allow the PCB to perform its intended function.

Some key points about PCBA:

• It follows after PCB fabrication when the bare PCB is manufactured.

• It involves mounting and soldering of components like ICs, resistors, capacitors etc. on the PCB.

• It requires precision and expert skills to ensure quality soldering and avoid errors.

• PCBAs form the core of most electronic gadgets and appliances we use.

• It is an assembly-line manufacturing process in most cases.

• The demand and growth for PCBA services is increasing globally due to rise of complex electronics and need for outsourcing.

So in summary, PCBA is the process of turning a bare PCB into a functional electronic assembly by adding and soldering all the requisite components. It is a crucial step in taking an electronic product design to mass production and market. The quality and efficiency of PCBA has direct impact on the product functioning, reliability and life cycle.

Hitech is an expert PCB manufacturing & assembly company that proudly supplies PCB assembly solutions to businesses of all sizes in China.

Our industry-leading PCB assembly processes create PCBs of the highest quality. Our expert team is made up of in-house trained professionals who have the experience and expertise to create dependable PCBs and utilise our PCB assembly technology. Through our strong network of well-proven PCB assembly and manufacturing partners, we can provide the most advanced and nearly limitless capabilities for your prototype or production PCB application. Save yourself the trouble that comes with the procurement process and dealing with multiple components vendors. Our experts will find you the best parts for your final product.

We offer the following PCB assembly services:

Quick-turn prototype printed circuit boardassembly

Turn-key printed wiring board assembly

Partial turn-key PCB assembly

Consignment assembly

RoHS compliant lead-free PCB assembly

Non-RoHS assembly

Conformal coating

Final box-build and packaging

Prototype PCB Assembly

For more, welcome to visit https://hitechcircuits.com/pcb....-assembly/printed-ci

If you have any needs of the PCB, please feel free to contact me by sales1@hitechpcb.com.