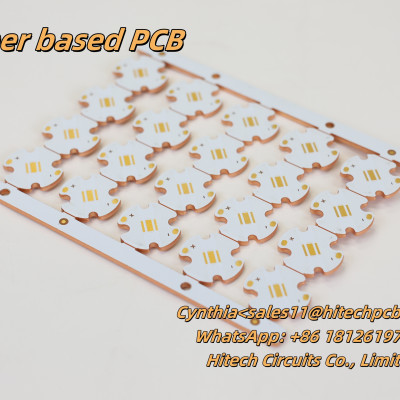

Awesome Aluminum PCB Board made in China Shenzhen Made by Hitech Circuits Co., Limited

Published By PCB Assembly_HitechCircuits_Roger Luo

- Location中国

- StatusIn stock

- TypeNew

Awesome Aluminum PCB Board made in China Shenzhen

An aluminum PCB board is a type of circuit board which has a thin layer of material bonded to one or both sides of an aluminum substrate. The thin layer materials are usually heat-conductive and electrically insulating dielectric materials. They are also called Metal Core PCBs (MCPCBs). The aluminum core used in the PCB is an excellent conductor of heat and electricity.

Because of this reason, the application of this PCB can be found in areas where crucial heat dissipation is happening like for high-power LED lights, electronics in the automotive, and some other devices where heat generation is high.

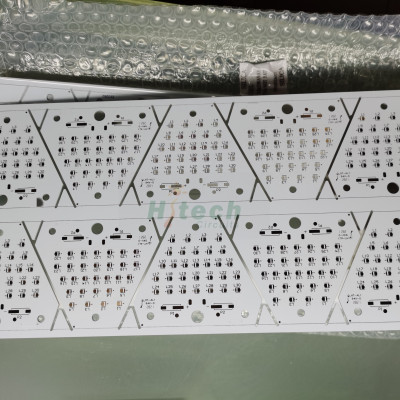

Aluminium PCB are metal-based, copper-clad laminates with a good heat dissipation function. Usually, Aluminium PCB refer to LED PCB board, which is the most important part of LED display and lighting products, etc.

Hitech Circuits Co., Limited is a professional aluminum pcb board, LED PCB manufacturer in China. Through 10 years of aluminum pcb board designing and manufacturing experience, Hitech are able to provide high quality and cost effective single layer, double layer and multi layer aluminum pcb boards to global customers.

Common Types of Aluminum PCB

Aluminum core PCB boards are used in applications where thermal management is crucial. There are generally three types of aluminium core PCBs classified based on their intended application.

1. Single-Layer Aluminum PCB

Single-Layer PCB: This PCB consists of a single layer of aluminum substrate PCB which also has a conductive layer of copper bonded to one of its sides. Single-layer aluminum PCB boards are comparatively simple in design and used in applications where heat management is the main concern. Some applications are LED lighting, automotive electronics, power supplies etc.

2. Double Layer Aluminum PCB

They have two layers of aluminum substrate with a conductive layer of copper which is bonded on both sides of the PCBs. They also have enhanced design flexibility and functionality compared to single-layer Alu PCBs. Because of the double-side feature, the components can be placed on both sides of the board. This will help in higher component density and complex design of circuits on the board. For applications requiring improved thermal performance and electrical isolation, such as power converters, motor drivers etc.

3. Metal-Core Printed Circuit Boards (MCPCBs)

They have a metal core substrate typically made of aluminum or copper alloy which is sandwiched between layers of dielectric material and copper foil. They have high thermal conductivity and heat dissipation capabilities when compared to standard PCBs like FR-4. This makes them ideal for high-power applications. MCPCBs are also called aluminium-clad PCBs. They are also available in single-layer, double-layer and multi-layer configurations.

The structure of aluminum printed circuit boards

Generally speaking, the PCB aluminum substrate is composed of a circuit layer, a thermally conductive insulating layer and a metal base layer; it can be divided into three layers:

Circuit layer: equivalent to the copper clad laminate of an ordinary PCB, the thickness of the circuit copper foil is 1 to 10 oz. The circuit layer (that is, copper foil) is usually etched to form a printed circuit to connect the various components of the assembly. Generally, the circuit layer requires a large current-carrying capacity, so thicker copper foil should be used, with a thickness of 35μm~ 280μm;

Insulation layer: The insulation layer is a layer of low thermal resistance thermally conductive insulating material. The thickness is 0.003 to 0.006 inches. It is generally composed of a special polymer filled with special ceramics. It has low thermal resistance, excellent viscoelasticity, thermal aging resistance, and can withstand mechanical and thermal stress. It is the core technology of aluminum-based copper clad laminates. Our aluminum printed circuit boards have obtained UL certification.

Metal base layer: The metal base layer is the support member of the aluminium pcb, which requires high thermal conductivity, generally aluminum plate will be used, copper plate can also be used (copper plate can provide better thermal conductivity), suitable for conventional machinery such as drilling, punching and cutting processing.

For more, welcome to visit https://hitechcircuits.com/pcb....-products/aluminum-p

If you have any needs of the PCB, please feel free to contact me by sales1@hitechpcb.com.